Background

In April 2023, I joined my university’s FSAE team out of a desire to acquire practical hands-on engineering experience. Additionally, I thought the premise of building an electric formula-style race car was super cool. I joined as a member of the chassis sub-team.

At the time, the team was coming out of a dormant phase, preparing to start developing a new vehicle after years of inactivity. The last time a vehicle was built was 2019.

This presented a unique opportunity to experience a product’s entire lifecycle from conceptualization and design, to manufacturing and testing.

That spring, I became acquainted with the scope of work that I would be doing the following semester.

I had not yet had the experience of actually doing a layup. To establish a foundation, I took a three-day course at my local community college during fall break. This training equipped me with the essential skills and techniques for working with carbon fiber.

In addition to lectures, the 3-day training included four hands-on labs. The first lab I completed was called the “potato chip lab.” I was initially curious about the name, but it made sense after the exercise. This introductory lab familiarized us with the process of laying down plies. There was no specific layup schedule or procedure; we simply constructed square specimens and cured them in the oven. After curing, many of the samples emerged warped — resembling potato chips. Following the lab, the instructor introduced the concept of layup schedules and explained how asymmetrical laminates can warp during curing due to internal stresses.

The second lab meant to demonstrate the strength of carbon fiber.

I learned the process of fabricating a panel, starting with preparing the plate, followed by correctly layering the plys by interpreting the layup schedule, bagging the setup to ensure proper vacuum sealing, and finally curing the panel.

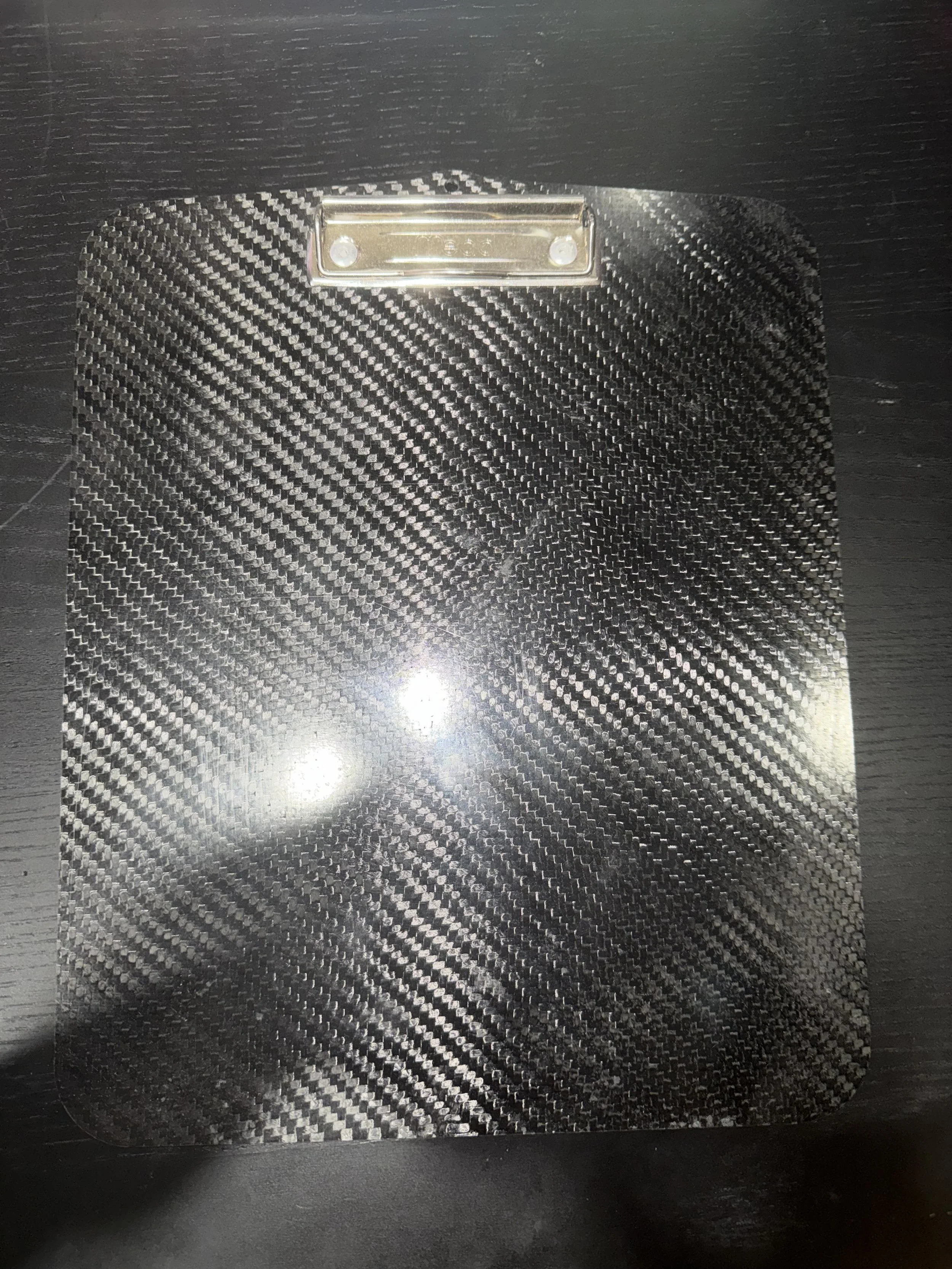

This is a clipboard I made using the wet layup method. Wet lay-up involves manually impregnating the plys with resin using a tool such as a roller or squeegee. The other type of layup is prepreg (pre-impregnated). Prepreg carbon fiber already contains resin that is partially cured. It is ready to be placed onto a mold and then fully cured in an oven.

Wet layups are good for applications that involve more complex shapes where relief cuts might be required.

Prepreg fiber eliminates variables such as consistency since it has a controlled resin-to-fiber ratio, ensuring consistent mechanical properties.